HSM Forestry Machines: Quality and Power

HSM Forestry Machines: Quality and Power

Made in Germany. The HSM product range includes Skidders, Forwarders, Harvesters, and combined forestry machines for both carried and dragging transport, designed for use in forestry.

Radio System

The remote controls adopted by Greifenberg are the result of years of field experience, ensuring optimal range and ergonomic usability. They are easily operable while wearing safety gloves and feature an extremely robust casing designed to withstand falls and heavy impacts. The convenient shoulder strap allows for single-handed operation, while the clearly labelled buttons ensure intuitive and efficient manoeuvring.

A high-capacity battery guarantees a full day's operation, with a spare battery and charger included as standard. The radio system’s intelligence is embedded in a secure key within the transmitter, storing all communication codes and protocols.

The remote control enables the execution of all operations typically performed via the machine’s touchscreen panel, including starting and stopping the diesel engine, adjusting cable speed, setting and updating load points, overriding preset limits via a dedicated bypass button, activating automatic work cycles for independent machine operation, controlling both traditional and motorised carriages, and regulating lifting and lowering speeds.

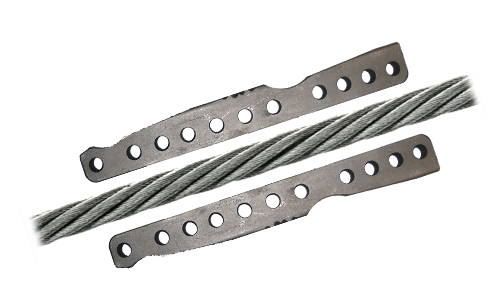

Additionally, the remote allows users to set a maximum lifting point, preventing accidental over-pulling of the hook, and to restrict cable unwinding, ensuring safe drum operation. In case of cable shortening, the lifting point can be easily recalibrated. The same remote control can integrate Fortronics electronic chokers, featuring an anti-accidental opening system for enhanced security.

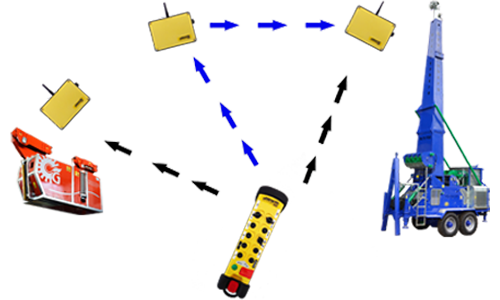

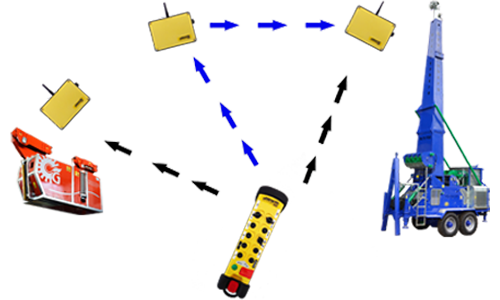

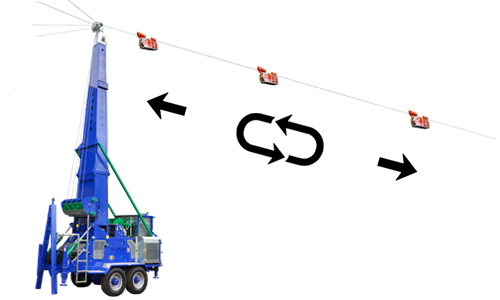

The Radio System includes a highly encoded and integrated frequency repeater. Multiple repeaters can be used simultaneously, creating an unlimited operating range while overcoming hills, buildings, and other obstacles. The compact and robust repeater is powered by a high-capacity rechargeable battery, ensuring continuous operation even during intensive workdays. It should be positioned at elevated points or alongside structures to maintain seamless connectivity between transmitter and receiver. Activation is simple, with a single-button setup and instant range reset.

Greifenberg understands extreme outdoor conditions, from sub-zero temperatures to scorching heat, snow, rain, and humidity. The Radio System is built to withstand the elements, boasting an IP65 protection rating, high-grade components, and anti-corrosion treated contacts. These features ensure unwavering reliability, delivering precise, responsive, and secure commands at all times. With transmitters, repeaters, and receivers ready for action, the Greifenberg Radio System guarantees uninterrupted performance in even the harshest working environments.

Automatic Cycle

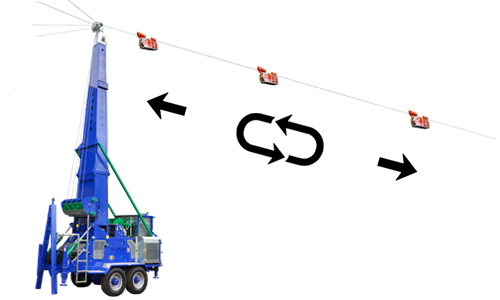

ATG, Automatic Travel Greifenberg, is the electronic control and management system—a true artificial intelligence that enables the machine to travel along the cable completely autonomously and in automatic cycles. The ATG system takes into account critical points such as supports, potential load entanglements, excessive power demands during ascents, overspeeding on descents, deceleration and acceleration speeds, and load point updates when necessary. It continuously coordinates operations with responsiveness, precision, and accuracy.

To activate ATG, the machine must first recognise the two extreme points of the line, which are stored as the "start line" and "end line" using an intuitive procedure on the control panel. Once set, it is possible to memorise the points along the line where the supports are located, which the system interprets as sensitive points. To ensure smooth travel, the electronic system allows users to define at what distance from the support the machine should decelerate and when it should accelerate again after passing it, returning to normal speed. These distances and the number of slowdowns can be customised depending on the travel direction and how the supports are approached.

For instance, when transporting heavy loads downhill, the system gradually slows down at an appropriate distance before the support, then quickly regains speed after passing it to avoid rope and load oscillations. Conversely, during uphill transport, it is sufficient to decelerate just before the support, as weight and gravity naturally contribute to slowing the movement.

Everything remains under control throughout the journey. Thanks to its pressure transducers and position encoders, the machine continuously monitors effort levels, and if it detects abnormal peaks (caused by snags or resistance), the automatic system is deactivated, stopping the journey while keeping manual operation available.

The ATG function also allows the load or unloading point to be updated via remote control. When the transport destination frequently changes to collect or deposit materials in different locations, the operator can simply activate the "store new endpoint" function directly from the remote control, and the machine will stop precisely at the newly determined location.

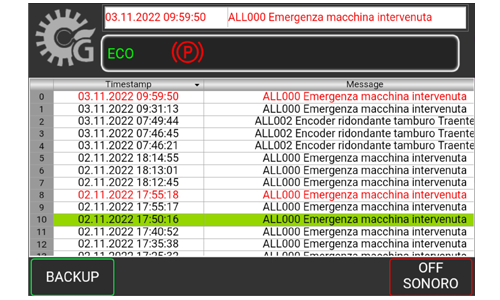

Backup Alarm

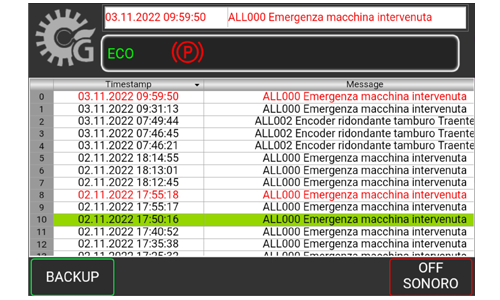

Total control, monitoring, and statistics. Every alarm, abnormal use, or operation outside set parameters is automatically recorded and stored in a dedicated memory. Data such as engine overspeed, overpressure, excessive speed, oil and water temperature alarms, and more are instantly registered. This makes it easy for the owner to monitor how the machine is being used, whether by employees or in the case of rental to third parties. Additionally, technical support interventions become faster, reducing maintenance costs. Information is readily available to optimise machine longevity and upkeep.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

Radio System

The remote controls adopted by Greifenberg are the result of years of field experience regarding operating range and ergonomic use. Designed for comfortable handling even with safety gloves, they feature an extremely robust case capable of withstanding drops and heavy impacts. With a convenient shoulder strap, they can be operated with just one hand, and thanks to buttons marked with specific icons, manoeuvres during use are extremely simple. A powerful battery ensures operation for an entire working day; additionally, the standard supply includes a spare battery and a charger. The brain of the radio system is housed in the key inserted into the remote control, where communication codes and protocols are stored.

All operations normally performed via the machine’s touchscreen panel can be carried out from the remote control. It allows users to start and stop the diesel engine, increase or decrease cable speed, set and update the end-of-line or loading point, make movements outside preset parameters using the dedicated “bypass” button, initiate the automatic work cycle to enable autonomous operation, control traditional trolleys by opening and closing the cable locks, and manage motorised trolleys by adjusting both the engine and the lifting/lowering speed.

The remote control can also set the maximum lifting point for the trolley to prevent accidental over-raising of the hook, as well as the maximum cable unwinding limit, ensuring the drum retains an adequate amount of cable. If the cable length is adjusted, the maximum lifting point can be reconfigured to match the new cable length. Additionally, the same remote control can integrate the management of Fortronics electronic chokers with an anti-accidental opening system.

The Radio System includes a fully coded and integrated radio frequency repeater. The remote controls can operate with one or multiple repeaters, effectively extending the working range infinitely and allowing signals to overcome hills, buildings, or any other obstacles. The repeater is housed in a compact yet sturdy casing, containing a powerful rechargeable battery that supports intensive daily operation. To ensure optimal connectivity between the transmitter and receiver, the repeater should be placed at the peaks of hills or at the sides of structures. Activation is straightforward, requiring just a single button press, while the working range can be reset with a simple click.

Greifenberg understands the challenges of working in outdoor conditions, with temperatures ranging from sub-zero to scorching heat, as well as exposure to snow, rain, and humidity. The Radio System is built to withstand the elements: rated IP65, featuring carefully selected components and contacts treated with anti-oxidation materials. These features guarantee a product designed for demanding applications, delivering maximum reliability to ensure precise, timely, and indisputable commands. Transmitters, repeaters, and receivers are ready for uninterrupted operation.

Automatic Cycle

ATG – Automatic Travel Greifenberg is an advanced electronic control and management system, effectively an artificial intelligence that enables the machine to autonomously travel along the cable route in a fully automated cycle. The ATG system takes into account critical factors such as supports, potential load entanglements, excessive power demand when ascending, over-revving when descending, deceleration and acceleration speeds, and load point updates when necessary. It continuously coordinates operations with responsiveness, precision, and accuracy.

To activate ATG, the machine must first recognise and store the two extreme points of the line, which are registered as the "start" and "end" of the route through an intuitive procedure on the control panel. Once these are set, users can mark the positions of any supports along the route, which the system will interpret as sensitive points. To ensure smooth travel, the electronic system allows users to set deceleration distances before a support and acceleration distances after passing it, returning to the normal operating speed. These distances and the number of slow-down points can be adjusted based on the direction of travel and the approach to supports.

For instance, when transporting heavy loads downhill, a gradual deceleration at an appropriate distance is necessary, followed by a quick acceleration after passing the support to prevent cable and load oscillations. Conversely, when travelling uphill, a slowdown is only needed just before the support, as the weight and gravity naturally contribute to the deceleration.

Throughout the journey, the machine maintains full control via pressure transducers and position encoders, constantly monitoring strain levels. If it detects abnormal peaks caused by obstructions or resistance, the system automatically deactivates, stopping travel but keeping manual operation available at all times.

The ATG function also allows the loading or unloading point to be updated via the radio control. When frequent changes to the drop-off or pick-up location are required, the operator can simply activate the "save new endpoint" function from the remote control. The machine will then stop exactly at the newly designated location.

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

CONTACT US FOR CONSULTATION

Don’t miss the opportunity to ensure the maximum quality and safety for your equipment! Contact us today for a personalized consultation and discover the effectiveness of our trolleys and original Greifenberg spare parts.