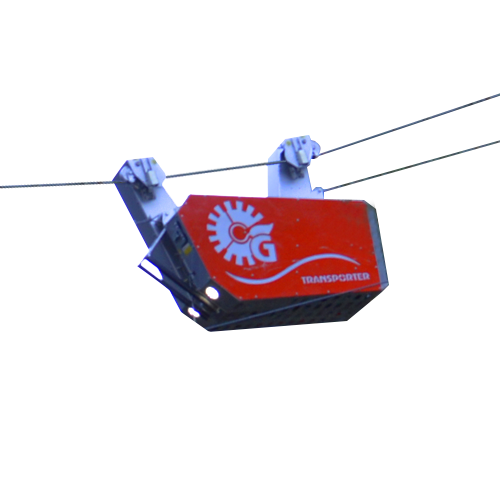

Motorised and radio-controlled trolleys for every need.

Advanced technology and high performance.

Motorised trolleys with lifting winch, self-propelled, traversing, with brakes on the supporting and traction ropes, box trolleys with baskets, and remote-controlled. Load capacities from 300 kg to 4 tons.

Capacity 6000 kg, Remote Controlled

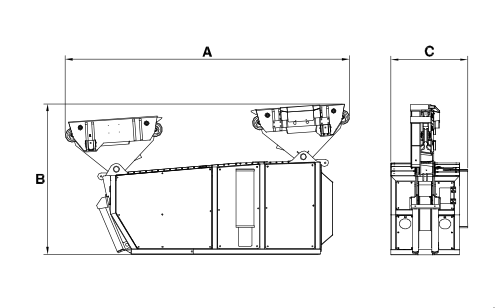

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Motorised with integrated lifting winch |

| Maximum load capacity | 4 ton |

| Pulley blocks on the load-bearing rope | no. 8 |

| Maximum translation speed | 4 m/s |

| Radio controllers | no. 2 |

| Line memorisation | As standard |

| Diesel engine power | 51,5 kw - 70 cv |

| Dry weight | 1450 Kg |

| LIFTING DRUM | |

| Lifting mode | with load bar |

| Rope capacity | 80 m |

| Rope diameter | 12 mm |

| Maximum lifting rope traction force | 6000 daN |

| Maximum lifting speed | 1 m/s |

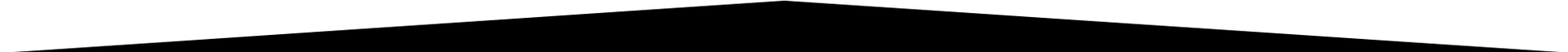

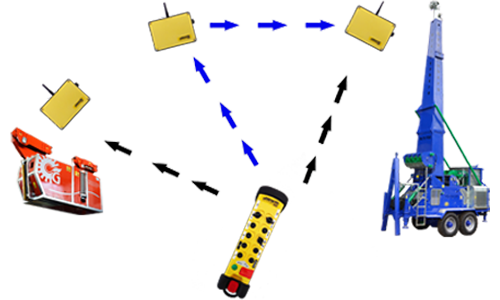

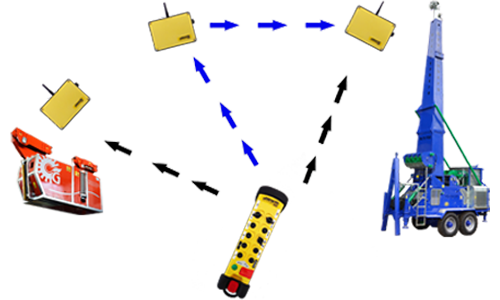

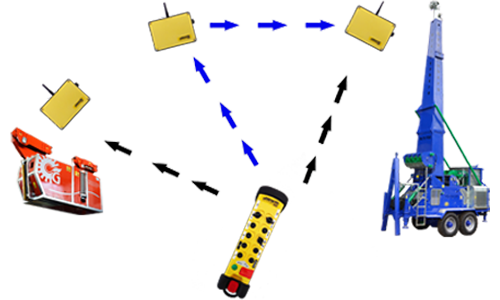

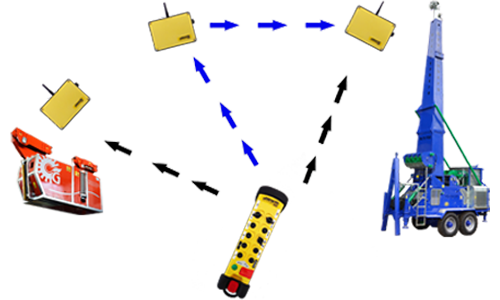

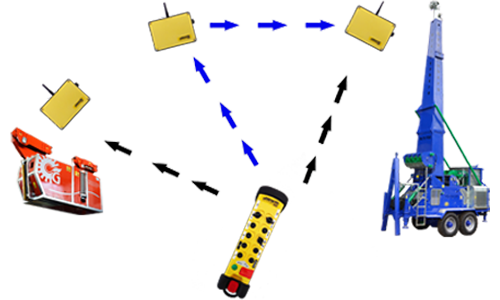

Radio System

The radio controls adopted by Greifenberg are the result of years of field experience regarding operational range and ease of use. They are comfortably usable with safety gloves, and feature an extremely robust "case" capable of withstanding drops and violent impacts. With the convenient shoulder strap, they can be held with one hand, and, thanks to buttons marked with specific icons, manoeuvres during use are extremely simple. A powerful battery ensures a full working day of use, and the standard supply also includes a spare battery and a charger. The brain of the radio system is located in the key inserted into the remote control, where communication codes and protocols are stored.

From the remote control, it is possible to perform all the operations that are usually carried out from the machine's touch screen panel. For example, it allows for the switching on and off of the diesel engine, increasing and decreasing the speed of the ropes, setting and updating the line end or load point, making movements outside the set parameters using the dedicated "by-pass" button, starting the automatic work cycle, controlling traditional trolleys by opening and closing the blocks on the ropes, and also performing all manoeuvres on motorised trolleys, controlling both the motor and the lifting and lowering speed.

Using the remote control, it is possible to set the maximum lifting point of the trolley to prevent the hook from being raised too much, as well as the maximum rope payout, avoiding the entire rope being unspooled from the trolley's drum. If the rope is shortened, the maximum lifting point can be reset to match the new rope length. The same remote control can also integrate the management of Fortronics electronic chokers with an anti-accidental opening system.

The Radio System includes a perfectly coded and integrated radio frequency repeater. The remote controls can operate with one or more repeaters, making the working distance limitless, and able to overcome bumps, buildings, and any obstacles, extending operational distances. The repeater is contained in a small, robust casing, and inside, a powerful rechargeable battery ensures operation even during long working days. The repeater should be placed on the tops of bumps or beside structures so that it finds a good connection both with the transmitter and receiver. Activation is very simple and is done with a single button, while the distance can be reset with a click.

Greifenberg understands the external working conditions, with temperatures ranging from sub-zero to scorching sun, snow, water, and humidity. The Radio System is unaffected by the weather: IP 65 rated, with selected components and contacts treated with anti-corrosive materials; these are the guarantees of a product designed for heavy-duty work. Maximum reliability ensures precise, timely, and undeniable commands. Transmitters, repeaters, and receivers are ready for non-stop work.

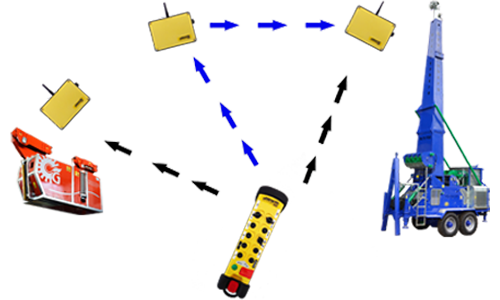

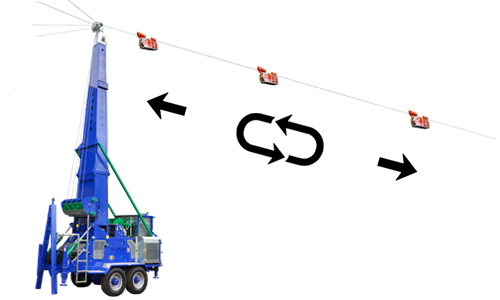

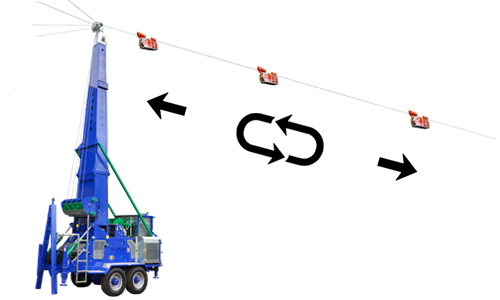

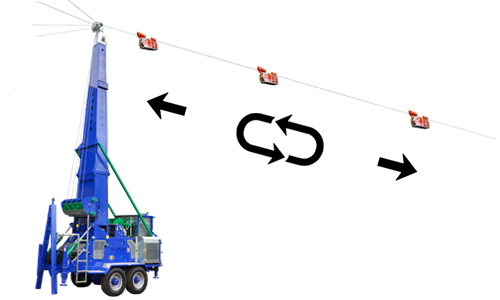

Automatic Cycle

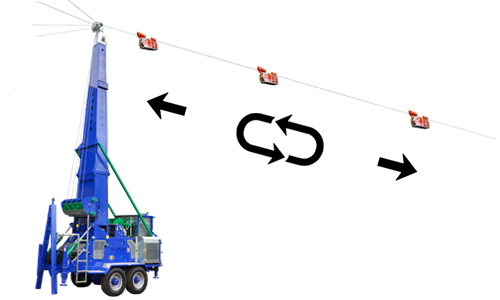

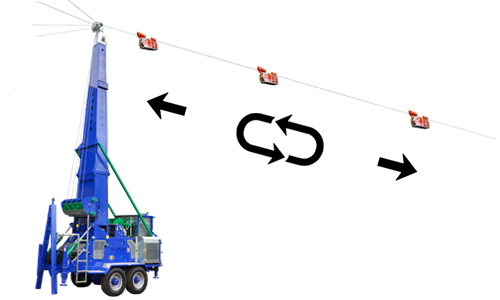

ATG, Automatic Travel Greifenberg, is the electronic control and management system, a true form of artificial intelligence, meaning the machine's ability to travel along the rope entirely autonomously and in automatic cycle. The ATG system takes into account various critical points, such as supports, potential load entanglements, excessive power demands on inclines, overspeed during descents, deceleration and acceleration speeds, and the updating of the load point if necessary. It continuously coordinates the work with responsiveness, precision, and accuracy.

To activate the ATG, the two extreme points of the line must be recognised by the machine, which are stored as "start of line" and "end of line" through an intuitive procedure on the control panel. Subsequently, it will be possible to store the points along the line where the supports are located, which will be interpreted as sensitive points. To ensure smooth travel, the electronic system allows you to set the distance at which you wish to slow down from a support and the distance at which you wish to accelerate again once passed, returning to normal speed. The distances and amounts of deceleration can be entered differently depending on which part of the journey you are in and, consequently, how you approach the supports. For example, when carrying heavy loads downhill, it is necessary to gradually slow down at a proper distance, while after passing the support, speed is quickly regained to avoid rope and load oscillations. On the other hand, if the transport is going uphill, it is enough to slow down near the support since weight and gravity already contribute to deceleration.

Everything is under control during the journey; in fact, the machine, thanks to its pressure transducers and position encoders, constantly monitors the effort, and if abnormal peaks are recorded (caused by jamming or resistance), it deactivates the automatic system, stopping the journey, but always making the manual mode available. The ATG function also allows the load or discharge point to be updated via the radio control. When the transport often needs to change the arrival point to pick up or deposit material in different locations, simply activate the “store new end point” function from the remote control, and the machine will stop its travel exactly at the specified location.

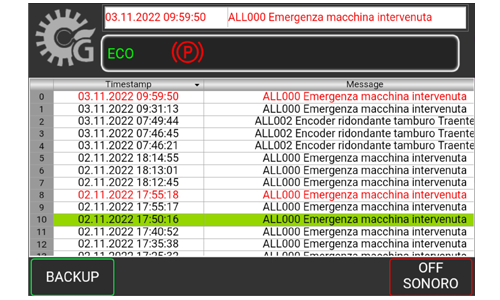

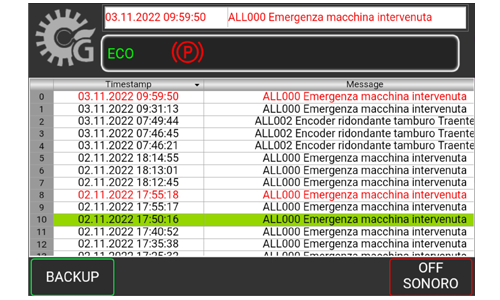

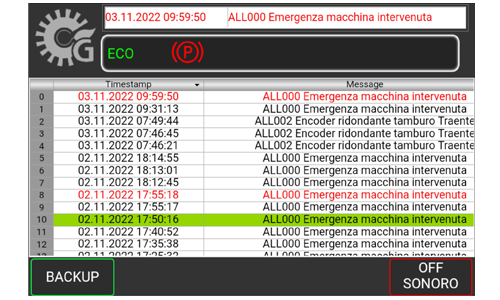

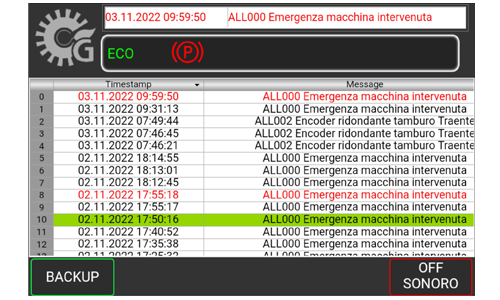

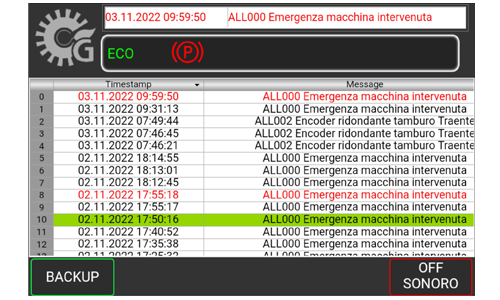

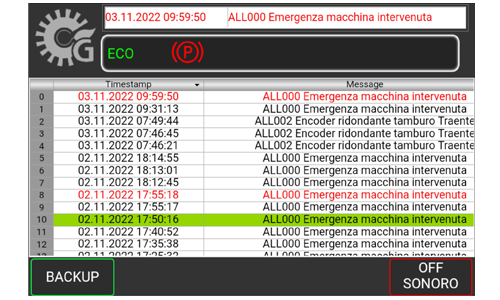

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

Capacity 6000 kg, Remote Controlled

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Motorised with integrated lifting winch |

| Maximum load capacity | 2 ton |

| Pulley blocks on the load-bearing rope | No. 4 |

| Maximum translation speed | 14 m/s |

| Radio controllers | No. 2 |

| Automatic Cycle | As standard |

| Diesel engine power | 28 kw - 38 cv |

| Weight with rope and fluids (without brake) | 790 Kg |

| Weight with rope and fluids (with brake) | 900 Kg |

| LIFTING DRUM | |

| Lifting rope capacity and diameter | 100 m d. 10 mm |

| Lifting rope traction force with full drum | 2000 daN |

| Lifting rope traction force at the first layer | 3540 daN |

| Maximum lifting speed | 1 m/s |

Radio System

The radio controls adopted by Greifenberg are the result of years of field experience regarding operational capacity and ease of use. They can be comfortably used with safety gloves and feature an extremely robust “case” that can withstand drops and heavy impacts. With the handy shoulder strap, they can be held with one hand, and, thanks to the buttons marked with specific icons, operations during use are extremely simple. A powerful battery ensures operation for an entire workday; additionally, the standard supply also includes a spare battery and a charger. The brain of the radio system is located in the key inserted into the remote control, where communication codes and protocols are stored.

From the remote control, all operations normally carried out from the machine's touch screen panel can be performed. It is possible to start and stop the diesel engine, increase or decrease the speed of the cables, set and update the end-of-line or loading point, make movements outside the preset parameters thanks to the dedicated "bypass" button, start the automatic work cycle, allowing the machine to operate autonomously, control traditional trolleys by opening and closing the locks on the cables, and perform all operations on the motorised trolleys, controlling both the motor and the lifting and lowering speed. Through the remote control, it is also possible to set the maximum lifting point of the trolley to prevent the hook from being erroneously raised too much, as well as the maximum cable unspooling to avoid unspooling all the cable wound on the trolley drum. If the cable is shortened, the maximum lifting point can be reset, adjusting it to the new length of the cable. The same remote control can also integrate the management of Fortronics electronic chokers with an anti-accidental opening system.

The Radio System includes a perfectly coded and integrated radio frequency repeater. The remote controls can operate with one or more repeaters, making the working distance virtually unlimited, and, most importantly, capable of overcoming bumps, buildings, and any type of obstacle, thus extending the operational range. The repeater is housed in a small, robust casing, and inside it, a powerful rechargeable battery ensures continuous operation even during an intense workday. The repeater should be placed on top of bumps or alongside structures, ensuring good interconnection both with the transmitter and the receiver. Activation is very simple, done with a single button, and the distance is reset with a click.

Greifenberg understands the external working conditions, with temperatures ranging from sub-zero to scorching sun, snow, water, and humidity. The Radio System is impervious to the elements: IP 65 rating, selected components, contacts treated with anti-oxidant materials; these are the guarantees of a product designed for heavy-duty use. Maximum reliability to ensure precise, timely, and irrefutable commands. Transmitters, repeaters, and receivers are ready for continuous operation.

Automatic Cycle

ATG, Automatic Travel Greifenberg, is the electronic control and management system, a true form of artificial intelligence, that is, the machine’s ability to carry out rope journeys entirely autonomously and in automatic cycle. The ATG system considers various critical points such as supports, potential load entanglements, excessive power demands on uphill slopes, overrevs during descents, deceleration and acceleration speeds, and updates the loading point if necessary. It constantly coordinates the work with responsiveness, precision, and accuracy.

To activate the ATG, it is necessary to recognise the two extreme points of the line, which are stored as "start line" and "end line" through an intuitive procedure on the control panel. Subsequently, it will be possible to store the points along the line where the supports are located, which will be interpreted as sensitive points. To ensure smooth travel, the electronic system allows you to set at which distance from the support you wish to slow down and at which distance after passing it you want to accelerate again and return to the normal speed. The distances and amount of deceleration can be entered differently depending on which direction you are travelling and thus the entry onto the supports. In fact, when transporting heavy loads downhill, it is necessary to gradually slow down at a suitable distance, while after passing the support, speed is quickly regained to avoid rope and load oscillation. On the other hand, if the transport is uphill, it is sufficient to slow down close to the support since the weight and gravity already contribute to the deceleration.

Everything is under control during the journey. In fact, the machine, thanks to its pressure transducers and position encoders, constantly monitors the effort, and if it registers any abnormal peaks (caused by jamming or conflicts), it deactivates the automatic system, halting the journey but always leaving manual mode available. The ATG function also allows you to update the loading or unloading point via the radio command. When the transport needs to frequently change the arrival point to pick up or drop off material in different places, simply activate the "store new end point" function directly from the remote control, and the machine will stop its journey precisely at the determined location.

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

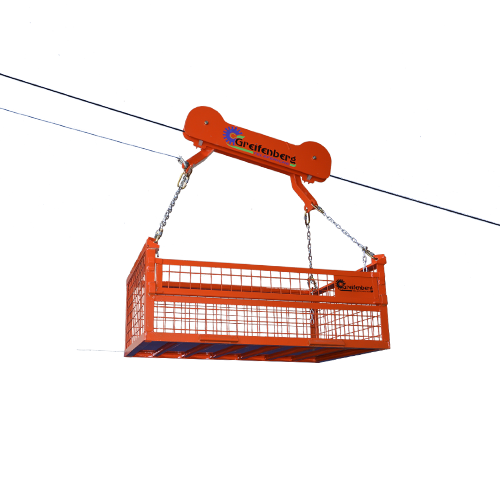

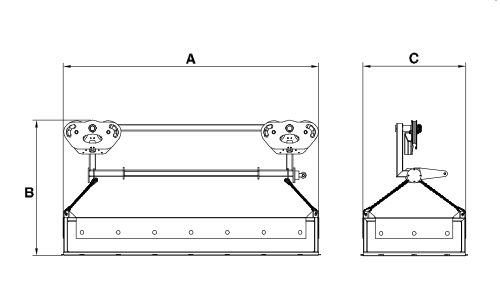

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Boxed |

| Maximum load capacity containment | 500 kg |

| Pulley blocks on the load-bearing rope | No.4 |

| Maximum translation speed | 10 m/s |

| Box dimensions | 2000 mm x 800 mm |

| Anti-derailment | As standard |

| Type of hauling rope anchorageType of hauling rope anchorage | Swivel hook |

| Load containment box | Customisable |

| Dry weight | 120 Kg |

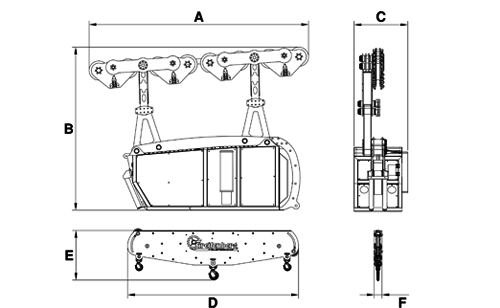

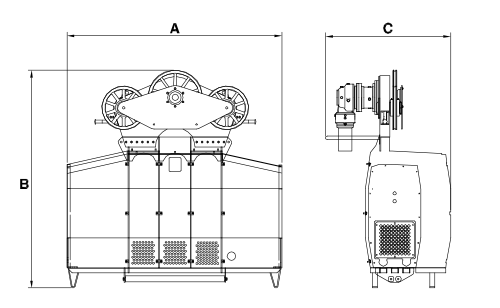

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Self-propelled motorised |

| Maximum load capacity | 3,2 ton |

| Pulley blocks on the load-bearing rope | No. 3 |

| Maximum translation speed | 4 m/s |

| Radio controllers | No. 2 |

| Automatic Cycle | As standard |

| End line memory | As standard |

| Diesel engine power | 74 kw - 101 cv |

| Diesel engine power | 74 kw - 101 cv |

| LIFTING DRUM | |

| Lifting cable capacity | 100 m |

| Lifting rope capacity and diameter | 11 mm |

| Lifting rope traction force with full drum | 3200 daN |

| Lifting rope traction force at the first layer | 5000 daN |

| Maximum lifting speed | 1,8 m/s |

Radio System

The radio remote controls adopted by Greifenberg are the result of years of field experience regarding operating capacity and user ergonomics. They can be comfortably used with safety gloves and feature an extremely robust "case" capable of withstanding drops and violent impacts. With a convenient shoulder strap, they can be handled with one hand, and thanks to buttons marked with specific icons, manoeuvres during use are extremely simple. A powerful battery ensures operation for an entire working day. Furthermore, the standard supply also includes a spare battery and a charger.

The "brain" of the radio system is located in the key inserted into the remote control, where communication codes and protocols are stored.

From the remote control, it is possible to perform all the operations that are typically carried out from the machine's touch screen panel. Indeed, it is possible to turn the diesel engine on and off, increase or decrease the speed of the ropes, set and update the end of the line or loading point, perform shifts outside of the set parameters thanks to the dedicated "bypass" button, start the automatic working cycle to make the machine operate autonomously, and control traditional trolleys by opening and closing the blocks on the ropes. It is also possible to carry out all operations on the motorised trolleys, controlling both the motor and the lifting and lowering speed.

Through the remote control, it is possible to set the maximum lifting point of the trolley to prevent the hook from being erroneously lifted too high, as well as the maximum unwinding of the rope, thus avoiding unwinding the entire rope on the trolley's drum. If the rope is shortened, the maximum lifting point can be reset to reflect the new length of the rope.

The remote control can also integrate the management of Fortronics electronic chokers with an anti-accidental opening system.

The Radio System includes a perfectly encoded and integrated frequency repeater. The remote controls can operate with one or more repeaters, making the working distance virtually limitless and able to overcome hills, buildings, and obstacles of any kind, extending the operational distances.

The repeater is contained in a robust, compact casing, with a powerful rechargeable battery inside, enabling operation even during an intense working day. The repeater should be placed on the peaks of hills or at the side of structures so that it finds good interconnection both to the transmitter and receiver. Activation is very simple and performed with a single button, and the distance is reset with just one click.

Greifenberg understands external working conditions, from subzero temperatures to scorching sun, snow, water, and humidity. The Radio System is weatherproof: IP 65 class, selected components, and contacts treated with anti-oxidant materials—these are the guarantees of a product designed for heavy-duty applications. Maximum reliability ensures precise, timely, and indisputable commands. Transmitters, repeaters, and receivers are ready for continuous operation without interruption.

Automatic Cycle

ATG, Automatic Travel Greifenberg, is the electronic control and management system, a true form of artificial intelligence, meaning the machine's ability to carry out cableway journeys completely autonomously and in automatic cycle. The ATG system takes into account various critical points such as supports, possible entanglements of the load, excessive power demands on ascents, over-revs on descents, deceleration and acceleration speeds, and the updating of the load point if necessary. It constantly coordinates the work with reactivity, precision, and accuracy.

To activate the ATG, the two extreme points of the line must first be recognised by the machine. These points are stored as "start of line" and "end of line" via an intuitive procedure on the control panel. Afterwards, it will be possible to store the points along the line where the supports are located, which will be interpreted as sensitive points. To achieve a smooth translation, the electronic system allows you to set the distance from the support at which we want to slow down, and the distance after passing it at which we want to accelerate again and return to the regular speed. The distances and the amount of deceleration can be entered differently depending on the direction of travel and, consequently, the entry onto the supports. In fact, when transporting heavy loads downhill, it is necessary to gradually slow down from a proper distance, and once the support is passed, speed is quickly regained to avoid rope and load oscillations. On the other hand, if the transport is going uphill, it is sufficient to slow down near the support, as the weight and gravity already provide natural deceleration.

Everything is under control during the journey. The machine, thanks to its pressure transducers and position encoders, constantly monitors the effort and, if it detects any abnormal peaks (caused by jams or resistance), it deactivates the automatic system, halting the journey but always making manual mode available. The ATG function also allows for updating, via the radio control, the load or unloading point. When the transport frequently changes the destination point to pick up or deposit materials in different locations, simply activate the "save new end point" function directly from the remote control, and the machine will stop exactly at the specified location.

Colour Display

The colour display for machine and line data provides greater accessibility, instant visual understanding, and easy parameterisation of the line, as well as a simplified procedure for synchronising the remote controls of the trolleys. The new series of displays allows for quick checks, providing constant information to the operator about the position, effort, position of the shoes, engine revolutions, fuel consumption, and fuel levels. The most important data is displayed both analogically and digitally to enhance the immediacy of reading.

Air transportable

Greifenberg machines and equipment that need to reach work positions without communication routes are designed with modular sections for quick disassembly, allowing the creation of units with a weight of less than 1100 kg. This feature makes it possible to transport them using conventional helicopters. Air transport reduces installation times, and the disassembly/assembly systems of the individual modules are designed to be simple, enabling the team to move the equipment quickly and safely.Greifenberg machines and equipment that need to reach work positions without communication routes are designed with modular sections for quick disassembly, allowing the creation of units with a weight of less than 1100 kg. This feature makes it possible to transport them using conventional helicopters. Air transport reduces installation times, and the disassembly/assembly systems of the individual modules are designed to be simple, enabling the team to move the equipment quickly and safely.

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

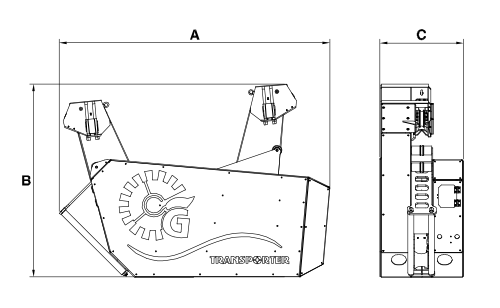

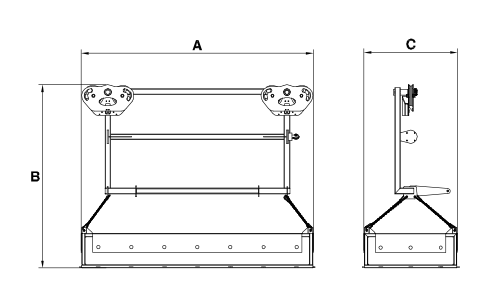

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Boxed |

| Maximum load capacity containment | 300 kg |

| Pulley blocks on the load-bearing rope | No. 2 |

| Maximum translation speed | 10 m/s |

| Box dimensions | 1200 mm x 800 mm |

| Anti-derailment | As standard |

| Type of hauling rope anchorage | Fixed Hook |

| Load containment box | Customisable |

| Dry weight | 80 Kg |

Radio System

The radio controls adopted by Greifenberg are the result of years of field experience regarding operating capacity and usability ergonomics. They are comfortably usable with safety gloves and feature an extremely robust "case" designed to withstand drops and violent impacts. The radio controls are equipped with a convenient shoulder strap, allowing one-handed use. Thanks to buttons marked with specific icons, maneuvers during operation are made extremely simple. A powerful battery ensures a full day of operation, and the standard supply includes a spare battery and a charger. The heart of the radio system is contained in the key inserted into the remote, where communication codes and protocols are stored.

From the remote, all operations typically performed via the machine's touch screen can be done. For instance, the user can power the diesel engine on and off, adjust the rope speeds, set and update the line end or loading point, make adjustments beyond set parameters with a dedicated “by-pass” button, start the automatic work cycle for autonomous machine operation, control traditional trolleys by opening and closing blocks on the ropes, and carry out all operations on motorized trolleys by controlling both the motor and lifting/lowering speed. Additionally, the remote allows for setting the maximum lifting point of the trolley, ensuring that the hook is not raised too high and preventing the rope from unspooling entirely from the trolley's drum. If the rope is shortened, the maximum lifting point can be updated accordingly to match the new rope length. The remote can also integrate the management of Fortronics electronic chokers with an accidental opening prevention system.

The Radio System includes a perfectly coded and integrated frequency repeater. The remotes can operate with one or more repeaters, enabling an infinite working distance, and more importantly, allowing the system to overcome bumps, buildings, and obstacles of any kind, extending the operational range. The repeater is housed in a robust, compact enclosure, and inside, a powerful rechargeable battery allows it to work throughout an intense workday. The repeater should be placed at the tops of hills or along structures to maintain a good connection both to the transmitter and receiver. Activation is simple, with a single button press to reset the distance with a click.

Greifenberg understands external working conditions that can vary from sub-zero temperatures to scorching sun, snow, water, and humidity. The Radio System is resistant to harsh weather conditions, with an IP65 rating, selected components, and contacts treated with anti-oxidant materials. These features guarantee a product designed for heavy-duty use, ensuring maximum reliability for precise, punctual, and unquestionable commands. Transmitters, repeaters, and receivers are all ready for continuous operation.

Automatic Cycle

ATG, Automatic Travel Greifenberg, is the electronic control and management system, a true form of artificial intelligence, meaning the ability of the machine to carry out ropeway journeys completely autonomously and in automatic cycle. The ATG system considers various critical points such as supports, potential entanglements of the load, excessive power requirements on ascents, overspeed in descents, deceleration and acceleration speeds, and updates to the loading point if necessary. It constantly coordinates the work with reactivity, precision, and accuracy.

To activate the ATG, the machine must recognise the two extreme points of the line, which are stored as "start of line" and "end of line" through an intuitive procedure on the control panel. Subsequently, it will be possible to store the points along the line where the supports are located, which will be interpreted as sensitive points. To achieve linearity in the translation, the electronic system allows you to set the distance at which you want to slow down from the support and the distance after passing it at which you want to accelerate back to ordinary speed. Distances and deceleration amounts can be set differently depending on which part of the journey you are in and the direction of entry onto the supports. In fact, when carrying heavy loads downhill, it is necessary to gradually slow down at a proper distance, while, after crossing the support, speed is quickly resumed to prevent rope and load oscillations. Conversely, when transporting uphill, it is sufficient to slow down close to the support since the weight and gravity already contribute to deceleration.

Everything is under control during the journey; indeed, the machine, thanks to its pressure transducers and position encoders, constantly monitors the effort and if it detects abnormal peaks (caused by blockages or resistance), it deactivates the automatic system, stopping the journey but always keeping the manual mode available. The ATG function also allows updating, via the radio command, the loading or unloading point. When the transport needs to frequently change the destination point to pick up or deposit material in different places, it is sufficient to activate the "store new end point" function directly from the remote control, and the machine will stop its movement precisely at the designated location.

Colour Display

The colour display for machine and line data provides greater accessibility, instant visual understanding, and easy parameterisation of the line, as well as a simplified procedure for synchronising the remote controls of the trolleys. The new series of displays allows for quick checks, providing constant information to the operator about the position, effort, position of the shoes, engine revolutions, fuel consumption, and fuel levels. The most important data is displayed both analogically and digitally to enhance the immediacy of reading.

Air transportable

Greifenberg machines and equipment that need to reach work positions without communication routes are designed with modular sections for quick disassembly, allowing the creation of units with a weight of less than 1100 kg. This feature makes it possible to transport them using conventional helicopters. Air transport reduces installation times, and the disassembly/assembly systems of the individual modules are designed to be simple, enabling the team to move the equipment quickly and safely.

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

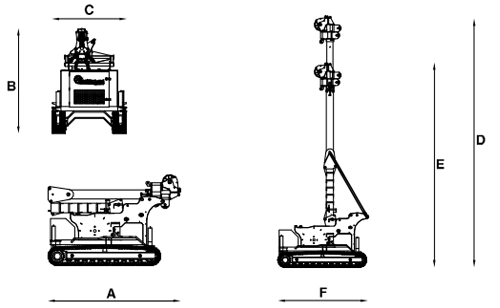

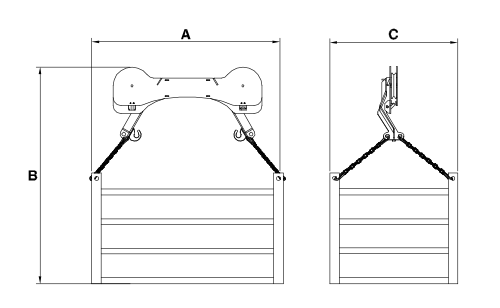

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Self-propelled motorised |

| Maximum load capacity | 3,2 ton |

| Pulley blocks on the load-bearing rope | No. 3 |

| Maximum translation speed | 4 m/s |

| Radio controllers | No. 2 |

| Automatic Cycle | As standard |

| End line memory | As standard |

| Diesel engine power | 74 kw - 101 cv |

| Indicative dry weight | 1700 Kg |

| LIFTING DRUM | |

| lifting cable capacity | 100 m |

| Lifting rope capacity and diameter | 11 mm |

| Lifting rope traction force with full drum | 3200 daN |

| Lifting rope traction force at the first layer | 5000 daN |

| Maximum lifting speed | 1,8 m/s |

Radio System

The radio controls used by Greifenberg are the result of years of field experience regarding operational capacity and user ergonomics. They are conveniently usable with safety gloves, have an extremely robust “case” that can withstand drops and violent impacts. With the convenient shoulder strap, they can be held with one hand, and thanks to buttons marked with specific icons, maneuvers during use are very simple. A powerful battery ensures operation for an entire workday. Additionally, the standard supply includes a spare battery and a charger. The brain of the radio system is located in the key inserted into the remote, where communication codes and protocols are stored.

From the remote, it is possible to carry out all the maneuvers that are normally performed on the machine’s touchscreen panel. In fact, it allows you to turn the diesel engine on and off, increase or decrease rope speeds, set and update the end line or load point, move outside preset parameters thanks to the dedicated “by-pass” button, start the automatic work cycle to operate the machine autonomously, control traditional trolleys by opening and closing the blocks on the ropes, and perform all maneuvers on motorized trolleys by controlling both the motor and the lifting and lowering speeds.

Through the remote, it is possible to set the maximum lift point of the trolley to prevent the hook from being accidentally lifted too much and to prevent the rope from being completely unwound from the trolley drum. If the rope is shortened, the maximum lift point can be reset according to the new rope length. The same remote can also integrate the management of Fortronics electronic chokers with an anti-accidental opening system.

The Radio System includes a perfectly coded and integrated frequency repeater. The radio controls can operate with one or more repeaters, making the working distance virtually unlimited, and especially capable of overcoming bumps, buildings, and obstacles of any kind, extending the operational distance. The repeater is housed in a small, robust case, and inside, a powerful rechargeable battery ensures it works throughout the day. The repeater should be placed at the top of bumps or alongside structures to ensure good communication both to and from the transmitter and receiver. Activation is very simple and is done with a single button, and the distance can be reset with a click.

Greifenberg understands the external working conditions, ranging from sub-zero temperatures to scorching sun, snow, water, and humidity. The Radio System is weatherproof, with an IP 65 rating, selected components, and contacts treated with anti-corrosion materials; these are the guarantees of a product built for heavy-duty use. Maximum reliability ensures precise, timely, and irrefutable commands. Transmitters, repeaters, and receivers are ready for non-stop work.

Automatic Cycle

ATG, Automatic Travel Greifenberg, is the electronic control and management system, a true artificial intelligence, meaning the ability of the machine to travel along the rope entirely autonomously and in automatic cycle. The ATG system takes into account various critical points, such as supports, potential load snags, excessive power demand when ascending, overrevs during descents, deceleration and acceleration speeds, and updating the loading point if necessary. It continuously coordinates the work with reactivity, precision, and accuracy.

To activate the ATG, the machine must recognise the two extreme points of the line, which are stored as "start of line" and "end of line" through an intuitive procedure on the control panel. Subsequently, it will be possible to store the points along the line where the supports are located, which will be interpreted as sensitive points. In order to achieve translational linearity, the electronic system allows you to set the distance at which to decelerate from the support and the distance at which to reaccelerate and return to normal speed after passing it. The distances and the amount of deceleration can be set differently depending on which direction the journey is being made and, consequently, the approach to the supports. In fact, when heavy loads are being moved downhill, it is necessary to gradually slow down from a suitable distance, whereas, after passing the support, speed is quickly regained to avoid rope and load oscillations. On the other hand, if the transport is going uphill, it is sufficient to decelerate near the support as the weight and gravity naturally enhance the deceleration.

Everything is under control during the journey. The machine, thanks to its pressure transducers and position encoders, constantly monitors the effort and, if it detects abnormal peaks (caused by snags or resistance), it deactivates the automatic system, stopping the journey, but always allowing manual operation. The ATG function also allows the update of the loading or unloading point via the radio control. When the transport often needs to change the arrival point to pick up or drop off material at different locations, simply activate the “store new end point” function directly from the radio control, and the machine will stop exactly at the designated location.

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

| TECHNICAL DATA | |

|---|---|

| Type of trolley | Motorised with integrated lifting winch |

| Maximum load capacity | 4 ton |

| Pulley blocks on the load-bearing rope | No. 8 |

| Maximum translation speed | 14 m/s |

| Radio controllers | No. 2 |

| Automatic Cycle | As standard |

| Line memorisation | As standard |

| Brake on the bearing rope | Direct cylinder |

| Diesel engine power | 51,5 kw - 70 cv |

| Weight with rope and fluids | 1350 Kg |

| LIFTING DRUM | |

| Lifting rope capacity and diameter | 160 m d. 12 mm |

| Lifting rope traction force with full drum | 3250 daN |

| Lifting cable traction force with 100 m of 12 mm diameter | 4000 daN |

| Lifting rope traction force at the first layer | 5800 daN |

| Maximum lifting speed | 2 m/s |

Radio System

The radio controllers adopted by Greifenberg are the result of years of field experience regarding operating capacity and ease of use. They are comfortably usable with safety gloves and have an extremely robust casing capable of withstanding drops and violent impacts. With the convenient shoulder strap, they can be held with one hand, and, thanks to buttons marked with specific icons, the operations during use are very simple. A powerful battery ensures a full day's work, and the standard supply also includes a spare battery and a charger. The brain of the radio system is in the key inserted into the remote control, where codes and communication protocols are stored.

From the remote control, it is possible to perform all the operations that are usually done from the machine's touchscreen panel. In fact, it is possible to turn the diesel engine on and off, increase or decrease the speed of the cables, set and update the end line or loading point, make movements outside the set parameters with the "by-pass" button, start the automatic work cycle, running the machine autonomously, control traditional trolleys by opening and closing the blocks on the cables, and also perform all operations on motorised trolleys, controlling both the motor and the lifting and lowering speeds. Through the remote control, it is possible to set the maximum lifting point of the trolley so that the hook is not accidentally lifted too high, as well as the maximum cable unwinding to avoid unwinding the entire cable wound on the trolley drum. If the cable is shortened, it is possible to reset the maximum lifting point to match the new cable length. The same remote control can also integrate the management of Fortronics electronic chokers with an anti-accidental opening system.

The Radio System includes a perfectly coded and integrated frequency repeater. The radio controllers can operate with one or more repeaters, making the working distance infinite, and, most importantly, capable of overcoming bumps, buildings, or any other obstacles, extending the operational range. The repeater is contained in a small, robust housing, and inside it, a powerful rechargeable battery allows work even during a full workday. The repeater should be placed at the tops of bumps or at the side of structures to ensure good interconnection between the transmitter and receiver. The activation is very simple and is carried out with a single button, and the distance is reset with a click.

Greifenberg understands the external working conditions with temperatures ranging from below freezing to scorching sun, snow, water, and humidity. The Radio System is weather-resistant: IP 65 rating, selected components, and contacts treated with anti-corrosive materials; these are the guarantees of a product designed for demanding tasks. Maximum reliability to ensure precise, timely, and indisputable commands. Transmitters, repeaters, and receivers are ready for non-stop work.

Automatic Cycle

ATG, Automatic Travel Greifenberg, is the electronic control and management system, a true artificial intelligence, meaning the machine's ability to carry out cable travel entirely autonomously and in automatic cycle. The ATG system takes into account various critical points such as supports, possible load blockages, excessive power demands during ascents, overspeeding during descents, deceleration and acceleration speeds, and updating the load point if necessary. It constantly coordinates the work with responsiveness, precision, and accuracy.

To activate the ATG, it is necessary for the machine to recognise the two extreme points of the line, which are stored as “start of line” and “end of line” through an intuitive procedure on the control panel. It is then possible to store the points along the line where the supports are located, which will be interpreted as sensitive points. To achieve a smooth translation, the electronic system allows the user to set the distance from the support at which they want to slow down and the distance after passing the support at which they want to accelerate back to normal speed. The distances and the amount of deceleration can be set differently depending on the part of the journey and the entry onto the supports. In fact, when carrying heavy loads downhill, it is necessary to gradually slow down from an appropriate distance, and once the support is passed, speed is quickly regained to avoid cable and load oscillations. On the other hand, when transporting uphill, it is sufficient to slow down close to the support as the weight and gravity already contribute to deceleration.

Everything is under control during the journey. In fact, the machine, thanks to its pressure transducers and position encoders, constantly monitors the effort, and if it detects abnormal peaks (caused by blockages or resistance), it deactivates the automatic system, stopping the journey, but always keeping manual mode available. The ATG function also allows updating the load or unloading point via the radio control. When the transport frequently changes the arrival point to pick up or deposit material in different places, simply activate the “store new end point” function from the remote control, and the machine will stop exactly at the specified location.

Colour Display

The colour display for machine and line data provides greater accessibility, instant visual understanding, and easy parameterisation of the line, as well as a simplified procedure for synchronising the remote controls of the trolleys. The new series of displays allows for quick checks, providing constant information to the operator about the position, effort, position of the shoes, engine revolutions, fuel consumption, and fuel levels. The most important data is displayed both analogically and digitally to enhance the immediacy of reading.

Air transportable

Greifenberg machines and equipment that need to reach work positions without communication routes are designed with modular sections for quick disassembly, allowing the creation of units with a weight of less than 1100 kg. This feature makes it possible to transport them using conventional helicopters. Air transport reduces installation times, and the disassembly/assembly systems of the individual modules are designed to be simple, enabling the team to move the equipment quickly and safely.

Backup Alarm

Total control, verification, and statistics. Every alarm, abnormal use, and operation outside the parameters are automatically recorded and stored in a dedicated memory. Data such as engine over-revving, overpressures, overspeed, oil and water temperature alarms, etc., are immediately recorded. It will be easy for the owner to monitor how the machine is used, both by their own staff and in the case of rental to third parties. Even for technical service interventions, everything becomes faster, limiting management costs. Information serving the durability and maintenance.

Remote Assistance

Our technicians with you, whenever you need, at your site to help you solve problems. Through remote assistance, simply activate a GPRS connection and allow access to your equipment. This always happens and exclusively with the operator's authorisation to the machine. Once connected, our electronic and hydraulic technicians can work on the machine as if they were right there on site. Maximum intervention speed and reduction of costs and waiting times. The innovation of safety always by your side.

CONTACT US FOR CONSULTATION

Don’t miss the opportunity to ensure the maximum quality and safety for your equipment! Contact us today for a personalized consultation and discover the effectiveness of our trolleys and original Greifenberg spare parts.