Efficiency in Felling and Delimbing

Superior Performance in Every Context

Processor Heads for Felling and Delimbing. SP Maskiner, made in Sweden with roller feed. Arbro, made in Finland with piston feed. Solutions for every need.

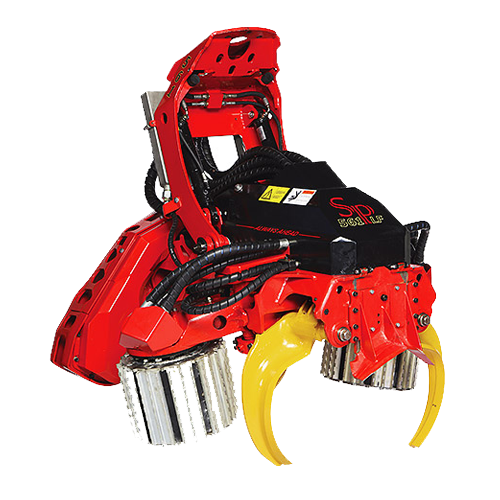

SP MASKINER PROCESSOR HEADS

All SP Maskiner processor heads are designed to make thinning, final felling, and delimbing as efficient as possible, and they are compatible with all brands and models of Harvesters. The LF series heads are characterised by their sleek and compact design, combined with maximum productivity and reliability. The heads are designed according to the low friction concept for maximum profitability. Whether working with initial thinning, final felling, or large amounts of hardwood, the LF series has the right processor head for the job. They come standard with high-level equipment; however, numerous different accessories are available to optimise the processor head for various needs, supports, and felling conditions.

Knife Profile

The delimbing knives are forged from high-strength steel and equipped with long cutting edges. This means that the limbs are cut rather than broken. This minimises friction during delimbing and allows the trunk to pass through easily.

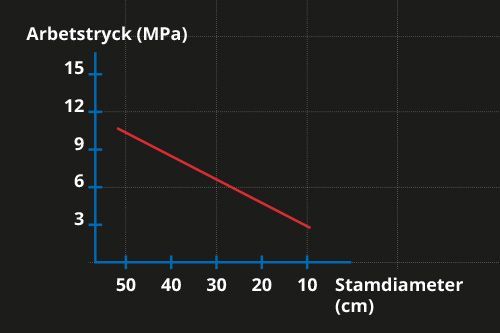

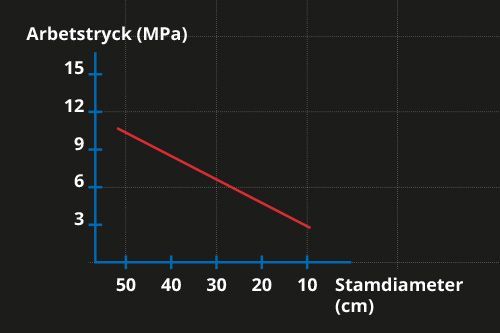

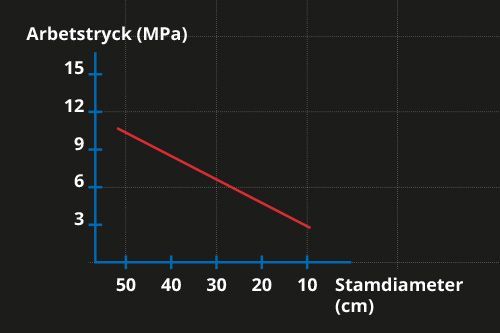

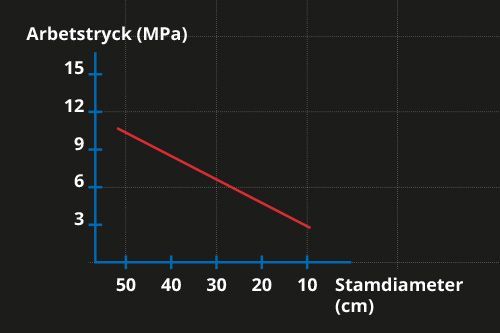

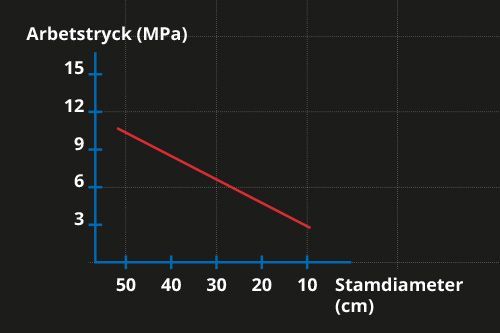

Proportional Pressure

Proportional pressure ensures that the harvester head automatically operates at the correct pressure in relation to the tree diameter. This means that the friction between the trunk and the harvester head is minimised, and the harvester head operates at maximum efficiency. Individual settings for tree species further maximise productivity.

Log Hold

LogHold is an evolution of proportional pressure, allowing the delimbing knife pressure against the trunk to be reduced without the risk of the trunk falling. If the trunk is about to fall, LogHold adjusts the knife pressure to ensure the trunk stays in the correct position. The amount by which the diameter can increase before LogHold activates is set in the control system. No additional sensors are required.

Proportional Angles

This smart solution means that when the harvester head is fully open, i.e., at the maximum tree size, the feed rollers are at their maximum angle and provide the highest load force against the trunk. As the feed rollers carry the trunk, the pressure on the delimbing knives can be reduced, which means less friction, and the harvester head can feed the trunk quickly and easily.

Knife Profile

The delimbing knives are forged from high-strength steel and equipped with long cutting edges. This means that the limbs are cut rather than broken. This minimises friction during delimbing and allows the trunk to pass through easily.

Proportional Pressure

Proportional pressure ensures that the harvester head automatically operates at the correct pressure in relation to the tree diameter. This means that the friction between the trunk and the harvester head is minimised, and the harvester head operates at maximum efficiency. Individual settings for tree species further maximise productivity.

Log Hold

LogHold is an evolution of proportional pressure, allowing the delimbing knife pressure against the trunk to be reduced without the risk of the trunk falling. If the trunk is about to fall, LogHold adjusts the knife pressure to ensure the trunk stays in the correct position. The amount by which the diameter can increase before LogHold activates is set in the control system. No additional sensors are required.

Proportional Angles

This smart solution means that when the harvester head is fully open, i.e., at the maximum tree size, the feed rollers are at their maximum angle and provide the highest load force against the trunk. As the feed rollers carry the trunk, the pressure on the delimbing knives can be reduced, which means less friction, and the harvester head can feed the trunk quickly and easily.

Knife Profile

The delimbing knives are forged from high-strength steel and equipped with long cutting edges. This means that the limbs are cut rather than broken. This minimises friction during delimbing and allows the trunk to pass through easily.

Proportional Pressure

Proportional pressure ensures that the harvester head automatically operates at the correct pressure in relation to the tree diameter. This means that the friction between the trunk and the harvester head is minimised, and the harvester head operates at maximum efficiency. Individual settings for tree species further maximise productivity.

Log Hold

LogHold is an evolution of proportional pressure, allowing the delimbing knife pressure against the trunk to be reduced without the risk of the trunk falling. If the trunk is about to fall, LogHold adjusts the knife pressure to ensure the trunk stays in the correct position. The amount by which the diameter can increase before LogHold activates is set in the control system. No additional sensors are required.

Proportional Angles

This smart solution means that when the harvester head is fully open, i.e., at the maximum tree size, the feed rollers are at their maximum angle and provide the highest load force against the trunk. As the feed rollers carry the trunk, the pressure on the delimbing knives can be reduced, which means less friction, and the harvester head can feed the trunk quickly and easily.

Knife Profile

The delimbing knives are forged from high-strength steel and equipped with long cutting edges. This means that the limbs are cut rather than broken. This minimises friction during delimbing and allows the trunk to pass through easily.

Proportional Pressure

Proportional pressure ensures that the harvester head automatically operates at the correct pressure in relation to the tree diameter. This means that the friction between the trunk and the harvester head is minimised, and the harvester head operates at maximum efficiency. Individual settings for tree species further maximise productivity.

Log Hold

LogHold is an evolution of proportional pressure, allowing the delimbing knife pressure against the trunk to be reduced without the risk of the trunk falling. If the trunk is about to fall, LogHold adjusts the knife pressure to ensure the trunk stays in the correct position. The amount by which the diameter can increase before LogHold activates is set in the control system. No additional sensors are required.

Proportional Angles

This smart solution means that when the harvester head is fully open, i.e., at the maximum tree size, the feed rollers are at their maximum angle and provide the highest load force against the trunk. As the feed rollers carry the trunk, the pressure on the delimbing knives can be reduced, which means less friction, and the harvester head can feed the trunk quickly and easily.

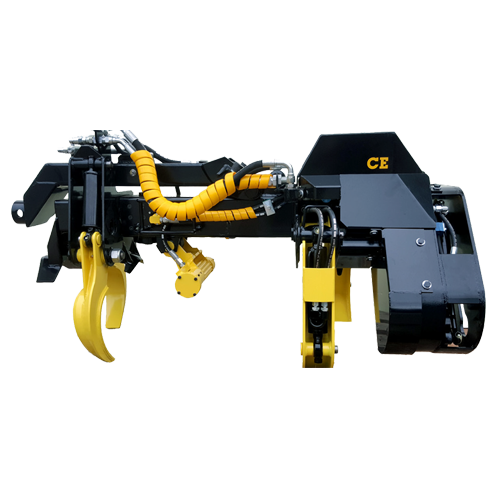

ARBRO Logging Processor Heads

The Arbro processor heads require low amounts of oil and pressure for their operation, meaning they can be installed even on small excavators. The advancement of the log is powered by hydraulic cylinders, ensuring great pushing force, allowing them to cut even large branches. With a reduced weight, it can handle diameters up to 40 cm. High-quality components with numerous accessories enable Arbro to handle every kind of situation.

• High-quality cylinders combined with oversized pins

• Easy and simple to use and maintain

• Thanks to robust knives/grabs, Arbro can easily handle fallen trees

• The debranching function is smooth thanks to the latest sensor guidance technology

• Arbromat or logger measurement unit with length and diameter

Knife Profile

The delimbing knives are forged from high-strength steel and equipped with long cutting edges. This means that the limbs are cut rather than broken. This minimises friction during delimbing and allows the trunk to pass through easily

Proportional Pressure

Proportional pressure ensures that the harvester head automatically operates at the correct pressure in relation to the tree diameter. This means that the friction between the trunk and the harvester head is minimised, and the harvester head operates at maximum efficiency. Individual settings for tree species further maximise productivity.

Log Hold

LogHold is an evolution of proportional pressure, allowing the delimbing knife pressure against the trunk to be reduced without the risk of the trunk falling. If the trunk is about to fall, LogHold adjusts the knife pressure to ensure the trunk stays in the correct position. The amount by which the diameter can increase before LogHold activates is set in the control system. No additional sensors are required.

Proportional Angles

This smart solution means that when the harvester head is fully open, i.e., at the maximum tree size, the feed rollers are at their maximum angle and provide the highest load force against the trunk. As the feed rollers carry the trunk, the pressure on the delimbing knives can be reduced, which means less friction, and the harvester head can feed the trunk quickly and easily.

CONTACT US FOR CONSULTATION

Don't miss the opportunity to ensure the highest quality and safety for your equipment! Contact us today for a personalised consultation and discover the effectiveness of our trolleys and original Greifenberg spare parts.